How much is a 3d printer? There is no definitive answer to this question. The price of 3D printers can vary widely, depending on the type and quality of the printer and the features and functions it offers. Some low-end 3D printers can be purchased for around $300, while high-end 3D printers can cost upwards of $10 000.

Cost and Considerations for Different Types of 3D Printing Processes

Fused Deposition Modeling (FDM)

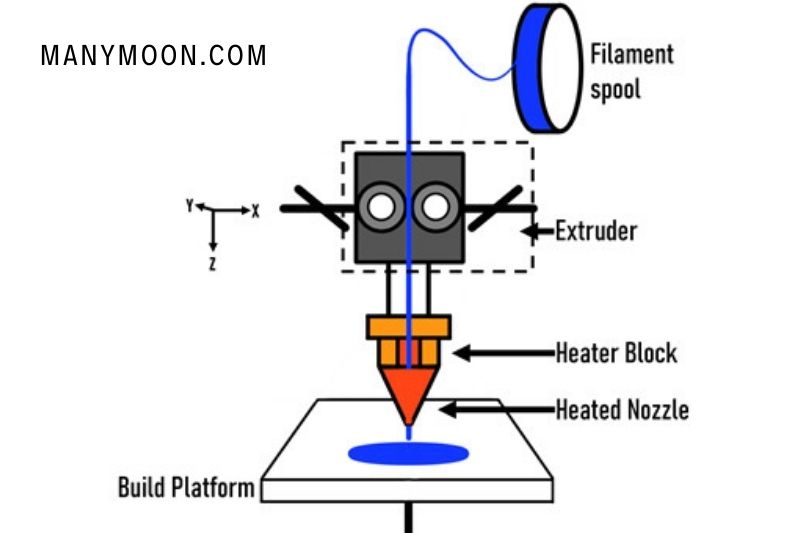

FDM (also known as fused filament manufacturing (FFF) is a method of printing that uses thermoplastic filament to build parts. A printer nozzle deposits layers in the build area.

FDM is the most popular form of 3D printing at the consumer level. The rise of hobbyist 3D Printers has fueled this. However, FDM printers for professionals and industrial use are also very popular.

FDM printers are the most affordable 3D printers. The entry-level DIY FDM 3D Printer Kits start at $200. These models can be toys or DIY projects, but you will need to spend considerable time setting up, calibrating, and tweaking the printer.

The success of these steps is crucial to the quality of your print. However, you will need to maintain them and repair them as needed. This makes it a good choice for someone with an engineering degree (in progress), lots of patience, and a lot of time.

Although hobbyist FDM 3D printers cost between $500 and $1500, they can be purchased as kits or assembled. They require less tweaking but still have many of the same drawbacks as low-cost 3D printers. The top models will have larger build volumes and more options for materials than low-temperature ones like PLA.

FDM 3D printers for professionals start at $2,500. Large-format professional FDM Printers start at $4,000, while industrial FDM Printers can easily run into the thousands. These printers can be calibrated and assembled right out of the box or auto-calibrated.

These printers offer superior print quality, a greater range of materials, higher build volumes, greater reliability, and easier maintenance. Manufacturers of professional 3D printers offer support for customers to resolve issues, unlike lower-cost printers.

FDM 3D printing materials costs are between $50 and $150/kg for standard and engineering filaments and $100 to 200/kg for support material. There might be cheaper alternatives, but this will come with a compromise in quality.

FDM printing is labor-intensive. FDM printing can be labor-intensive for many designs, particularly complex ones. Support structures are required to print successfully. These structures must be either removed manually or dissolved in the case of soluble supports. Parts must be manually processed to remove layers and achieve a high-quality finish.

Stereolithography (SLA)

SLA 3D printers make liquid resins into hardened plastic using a laser. This is called photopolymerization. SLA is a popular process among professionals because of its high resolution, precision, and material versatility.

SLA parts are the most precise, clearest, and smoothest of all 3D plastic printing technologies. But the real benefit lies in their versatility. SLA resin formulations have various optical, mechanical, and thermal properties that match the standard, engineering, and industrial thermoplastics.

SLA technology was once only available in expensive, high-end industrial 3D printers. Businesses can now get industrial-quality SLA with the Formlabs Form 3 printer for only $3,500. The Form 3L is available in large formats starting at $11,000

SLA 3D printers come pre-assembled and calibrated right out of the box. These professional tools are reliable for production and require little maintenance. In the rare event of an issue, customer support can help you.

SLA resins are relatively inexpensive at $149-$200/L, depending on the standard or engineering resin.

SLA printers can be used easily, and most workflow steps, such as washing and post-curing, can be automated to cut down on labor. The printed parts are high-quality right out of the printer. They only require simple post-processing to remove any support marks.

Selective Laser Sintering (SLS)

The SLS 3D printer uses a powerful laser to fuse small pieces of polymer powder. Unfused powder helps support the part while printing, eliminating the need for support structures. This makes SLS 3D printers ideal for complex geometries such as interior features, undercuts, and thin walls.

SLS-printed parts have excellent mechanical properties and strength comparable to those made from injection-molded parts. SLS printing is the most popular plastic 3D printer for industrial applications.

SLS was once only available in complex, large-format 3D printers starting at $200,000. Businesses can now get industrial SLS printing from Formlabs with the Fuse 1 printer. A complete setup includes post-processing, powder recovery, and a total cost of $31,845.

SLS printers are similar to SLA printers in that they come pre-assembled and calibrated right out of the package. They are reliable, designed for 24/7 production, and include fast support and training.

SLS printing costs around $100/kg for nylon materials. SLS printing does not require support structures, and the unfused powder can be re-used, which reduces material costs.

Because parts are high quality and ready to print, SLS is the most labor-intensive 3D plastic printing process.

Metal 3D Printing

There are many 3D printing options for metal 3D printing beyond plastics.

Metal FDM

Metal FDM printers are similar to traditional FDM printers. They extrude metal rods that are held together with polymer binders. The “green” parts are then sintered in a furnace to remove the binder.

Selective Laser Melting (SLM) and Direct Metal Laser Sintering (DMLS).

SLM and DMLS printers are similar to SLS printers but fuse metal powder particles layer by layer with a laser instead of using polymers. SLM and DMLS 3D Printers can create strong, precise, and complex metal products. This process is ideal for aerospace, automotive, and medical applications.

Although metal 3D printer costs have begun to drop, at $100,000 to $1,000,000, the cost of these printers is still prohibitive for most businesses.

SLA 3D printing can also create metal parts with less cost and greater design freedom. It takes much longer than traditional casting processes.

Cost Per Part: Calculating 3D Printing Costs

To calculate the cost per part, you must account for equipment ownership, material costs, and labor. Understanding the cost components is important. It also helps to know the questions you should ask to assess alternative production methods and discover hidden costs.

Equipment Ownership

Equipment ownership costs include fixed costs such as a 3D printer, maintenance, service contracts, installation, and maintenance. These expenses are not dependent on whether your 3D printer is active or producing dozens of parts per week.

Divide equipment ownership costs by adding all the anticipated fixed costs over the machine’s life, and then divide that sum by the expected number of parts it will produce. The equipment ownership cost per part will be lower if your 3D printer is more productive and efficient.

Desktop 3D printers have made great strides in lowering equipment ownership costs in recent years. Equipment ownership costs can be negligible if they are priced 10-100% lower than traditional industrial 3D printing machines and can produce thousands of parts in their lifetime.

Materials and Consumables

Variable costs include raw 3D printing materials, consumables, and other supplies required to make parts. The number of parts produced will affect the cost.

Calculate the 3D printing material required to make a single part. Then multiply that number by the material’s cost. Add in any waste or other consumables. Equipment ownership costs drop as production increases, but material costs for 3D printing tend to flatten quickly.

It is important to know what materials are required to make the parts. The cost of 3D printing consumables can vary. You should also be aware that not all 3D printers can work with third-party materials.

Labor

3D printing is a way to replace traditional manufacturing processes and save time. However, depending on the 3D printer technology used, it can still be labor-intensive.

The desktop 3D printers for professionals are optimized for ease of use. Hobbyists and DIY 3D printers require more work, while skilled operators may need to perform routine maintenance or change materials on industrial machines.

The post-processing steps vary depending on the 3D printing process. However, they all involve cleaning and removing excess material or supports.

Some of these tasks can be automated. Formlabs Form Wash or Form Cure do washing and curing Formlabs SLA 3D Printers easier. Fuse Sift provides turnkey post-processing and powder recovery system for Fuse 1 SLS Printers.

High-quality parts can be achieved using more advanced processes such as SLA or SLS. However, FDM parts will require manual post-processing to improve quality and remove layers.

Considerations Beyond Direct Costs

It is relatively simple to calculate investment, material, and labor costs. What about indirect costs? These are factors that can be difficult to quantify but still impact your business. Let’s look at the main considerations when comparing desktop printing with outsourcing or other production methods.

Time savings: Imagine if your products could be brought to market much faster. You could also reduce the time it takes to produce your products. 3D printing makes prototyping and production easier, which will help you save time and keep up with the rest of your competitors.

You get better results with 3D printing. It allows you to make more iterations and fail faster while producing better products. Identifying and correcting design problems early can help avoid costly production changes and design revisions.

Communication: High-quality parts and prototypes allow you to communicate better with clients, customers, suppliers, and other stakeholders. Avoid costly mistakes and confusion.

Protect your IP: Are you working with sensitive information? Parts created in-house mean that you don’t have to disclose intellectual property (IP) to third parties. This reduces the risk of IP theft or leakage.

Outsourced Production vs. In-House 3D Printing

If you need 3D printing occasionally or for large parts that require non-standard materials, outsourcing production to labs or service bureaus is a good option. Most bureaus have multiple 3D printing processes, including SLA, SLS, and FDM. They can also offer advice on different materials and provide value-added services like design or advanced finishing.

Outsourcing has two main drawbacks: cost and lead-time. The greatest benefit of 3D printing over traditional manufacturing is its speed. This can quickly decrease if an outsourced part takes several days or even weeks to arrive. Outsourcing becomes more expensive as a result of growing production and demand.

Desktop 3D printers can be a great option when you need parts quickly. A professional 3D printer may be more cost-effective than a desktop 3D printer depending on how many parts you need and your printing volume. This can make it possible to invest in a printer for months.

You can buy as many capacity units as you need for your business or add more machines. You can print parts in multiple materials by using multiple 3D printers. Service bureaus can supplement this flexible workflow for larger parts and other unusual materials.

3D Printing Cost Calculator

To calculate cost per piece, lead time, and compare alternatives to determine if a solution is worth it for your business, you would need to create a complicated spreadsheet and get all the information from the manufacturer.

You can skip all this by using our interactive 3D printing calculator. It will calculate the cost of 3D printing and the lead time for Formlabs 3D printers. Also, it will allow you to compare production times and savings with other methods.

Relevant post: How To Find WPS Pin For Printer? Top Full Guide 2022

FAQ

Is owning a 3D printer illegal?

Three ways to break the law with 3D printing

Patented objects: A patent is a right that protects an invention or innovation. This means that no one can create, use or sell a product except the patent holder. Patent infringement could be brought against the patent holder if 3D printing is done to a patent object.

Is it worth getting a 3D printer?

So, in short: 3D printing can be a worthwhile investment once you have mastered the basics and can produce quality prints that can also be used for prototyping, repairing household items, and even making money in some cases.

Are 3D printed guns possible?

Plastic guns are often used to evade gun control and are used for improvised firearms. However, 3D-printed steel guns are commonly seen as a way for legitimate gun makers to surpass traditional design limits. It is possible to make fully-plastic guns, but they are usually very short-lived.

Can you 3D print a car?

Additive manufacturing is a game-changer in the automotive industry. 3D printing technology was once a tool for prototyping, and it is still. It’s now being used in car manufacturing. It’s possible to build cars with 3D printing.

Conclusion

3D printing is the process of making a three-dimensional solid object from a digital model. The benefits of using a 3D printer are many. Still, Selective Laser Sintering (SLS) printers are the best option for businesses because they offer high quality, durable prints and are reliable and efficient.